- Top

- Corporate information

- Sustainability

- Environmental Initiatives

- Chemicals Strategy for Sustainability

Chemicals Strategy for Sustainability

Product Chemicals Management

The IRISO Group is committed to complying with the environmental laws and regulations of each country, such as the EU RoHS Directive and EU REACH Regulation, as well as to meeting the requirements of our customers. Our product chemicals management is based on practices at the supply chain level, and we have set up our "Green Procurement Standards" to ensure we and our suppliers play a part in the supply chain sustainable management. We are dedicated to the production of eco-friendly products by managing the green process from purchasing raw materials, and components and parts through manufacturing and shipping products. .

We have also installed an array of chemical analyzers and conducted periodic inspections to prevent the inflow and outflow of prohibited substances.

Supply Chain Management

We ensure chemicals in products (CIP) are effectively managed across the entire supply chain. We are committed to communicating reliable information on chemicals in products.

Chemical Reduction Strategy

We are committed to reducing risks associated with using chemicals, in compliance with environmental laws and policies in countries around the world, such as the EU RoHS Directive and the EU REACH Regulation.

・100% Ozone Depleting Chemical (ODC) Free Production

We started reducing the ODC substances in 1990 and achieved 100% ODC-free production by 1993. Since then, we have not used any ozone depleting chemicals (ODC) in manufacturing processes or for materials used in manufacturing.

- EU RoHS compliant

Regarding our response to the EU RoHS Directive, we are already in compliance with RoHS, except for solder plating products, which some customers have requested. We have not had any products that use the four specific phthalates that became subject to RoHS regulations in 2019 since before the regulations came into effect.

・EU REACH Compliance

Since official REACH SVHC was published in November 2008, we have kept up to date with the latest REACH SVHC, which is updated once or twice a year. We also communicate information on chemicals in our products to customers on their request.

・Transition to Lead-Free Products

From 2000, we started manufacturing lead-free products in compliance with the RoHS directive,

which specifies the maximum concentration value by weight for lead, 0.1wt% (1000ppm).

We were already prepared to supply lead-free alternatives for existing products by 2003

and have gradually shifted to lead-free manufacturing since then.

New products that have been developed since 2006 are lead-free, and all products delivered to our customers are also lead-free.

(Excluding products for which some customers have requested maintenance parts. Sales volume of these products will be 0.03% in fiscal year 2023 and 0.02% in fiscal year 2024.)

Chemicals in Products Analyzer and Use

Since 2006, the group plants have started purchasing X-ray fluorescence analyzers (EDX), and all of them have it now. They use it for incoming and outgoing goods inspections. Other analyzers are owned by the IRISO group.

These analyzers enable us to confirm the non-inclusion of any RoHS 10 substances in the products so that we can ensure that harmful substances are not brought into the group plants during incoming inspections, to establish a quality assurance system that can build customer trust in the products, as well as performing a quick primary analysis when a product defect is found.

| Energy Dispersive X-Ray fluorescence (EDX) |

Inductively Coupled Plasma Atomic Emission Spectroscopy (ICP) |

Fourier Transform Infrared Spectroscopy (FT-IR) |

Heat Desorption Mass Spectrometer (Phthalates inspection system) |

|

|---|---|---|---|---|

| CIP Analyzer |  |

|

|

|

| Use | Possible to measure five elements (cadmium, lead, mercury, chromium, and bromine), which are prohibited by the RoHS Directive, except hexavalent chromium and specific bromine. |

Possible to closely analyze three elements (cadmium, lead, and mercury), which are banned by the RoHS Directive |

Possible to check whether phthalate ester, etc. is contained in products. | Possible to measure four specific phthalate esters, etc. and brominated flame retardants (DBDE), which are prohibited by the RoHS Directive |

Chemicals Management in Manufacturing

There are no use and emissions of NOx (nitrogen compounds) and SOx (sulfur compounds) in manufacturing.

We ensure that all chemicals included in the PRTR (Pollutant Release and Transfer Register) list are properly managed through identifying and aggregating them based on the PRTR system to estimate chemicals handlings, emissions, and transfers, etc. Among chemicals in the PRTR list, nickel compounds contained in nickel sludge and waste solutions, which are produced in the process of plating at the Ibaraki plant, are subject to legal reporting.

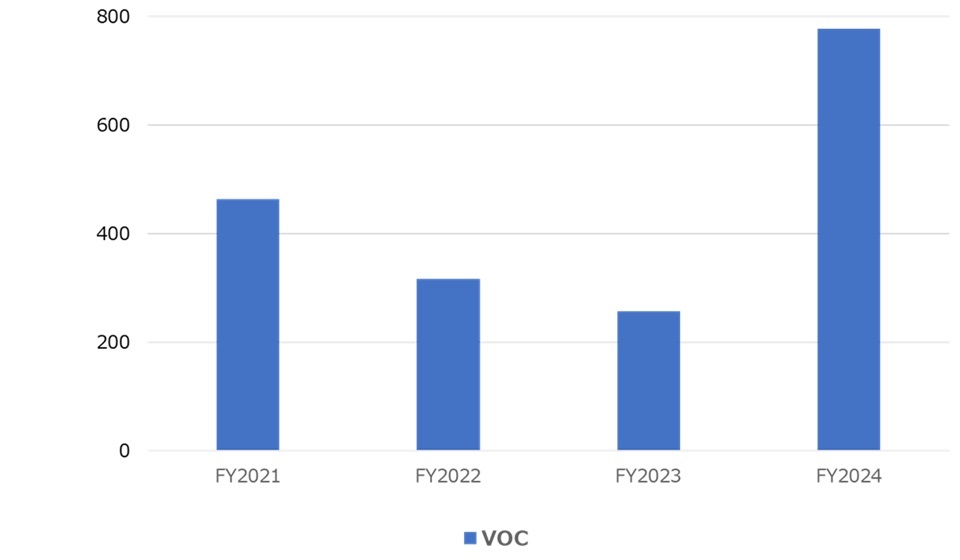

Regarding VOCs (volatile organic compounds), the flux used to improve the solderability of terminals in some products produced at Shanghai Plant contains isopropyl alcohol, a VOC. Although the number of affected products is small, at approximately 0.1% of the quantity delivered to customers in fiscal year 2024, we will consider reviewing our usage methods in the future.

(Estimated change in the transfers of PRTR chemicals subject to legal reporting)

| unit | 2022.3 FY2021 |

2023.3 FY2022 |

2024.3 FY2023 |

2025.3 FY2024 |

|

|---|---|---|---|---|---|

| Nickel Compounds | kg | 667.2 | 796.6 | 785.0 | 844.0 |

| unit | 2022.3 FY2021 |

2023.3 FY2022 |

2024.3 FY2023 |

2025.3 FY2024 |

|

|---|---|---|---|---|---|

| VOC | kg | 464.1 | 316.5 | 256.7 | 778.1 |